Automatic SpotWelder

Efficiency Redefined:

Accelerate your production timelines with swift and efficient spot welding, optimizing the manufacturing process without compromising on quality.

Automated Precision:

Our Automatic Spot Welder employs advanced automation technology to achieve spot-on precision in every weld, ensuring the structural integrity and longevity of your battery packs.

Versatility in Design:

Adapt to the evolving landscape of electric vehicles with a welder designed for versatility, accommodating various battery pack sizes and configurations.

Reliability:

Craft battery packs with utmost reliability, meeting the stringent quality standards required for electric vehicle applications.

Effortless Customization:

Harness the power of our custom CNC control to effortlessly adapt to diverse battery pack designs, ensuring a tailored approach to your production needs.

Time and Cost Efficiency:

Streamline your manufacturing operations with a focus on efficiency, reducing both time and costs associated with the production of high-quality battery packs.

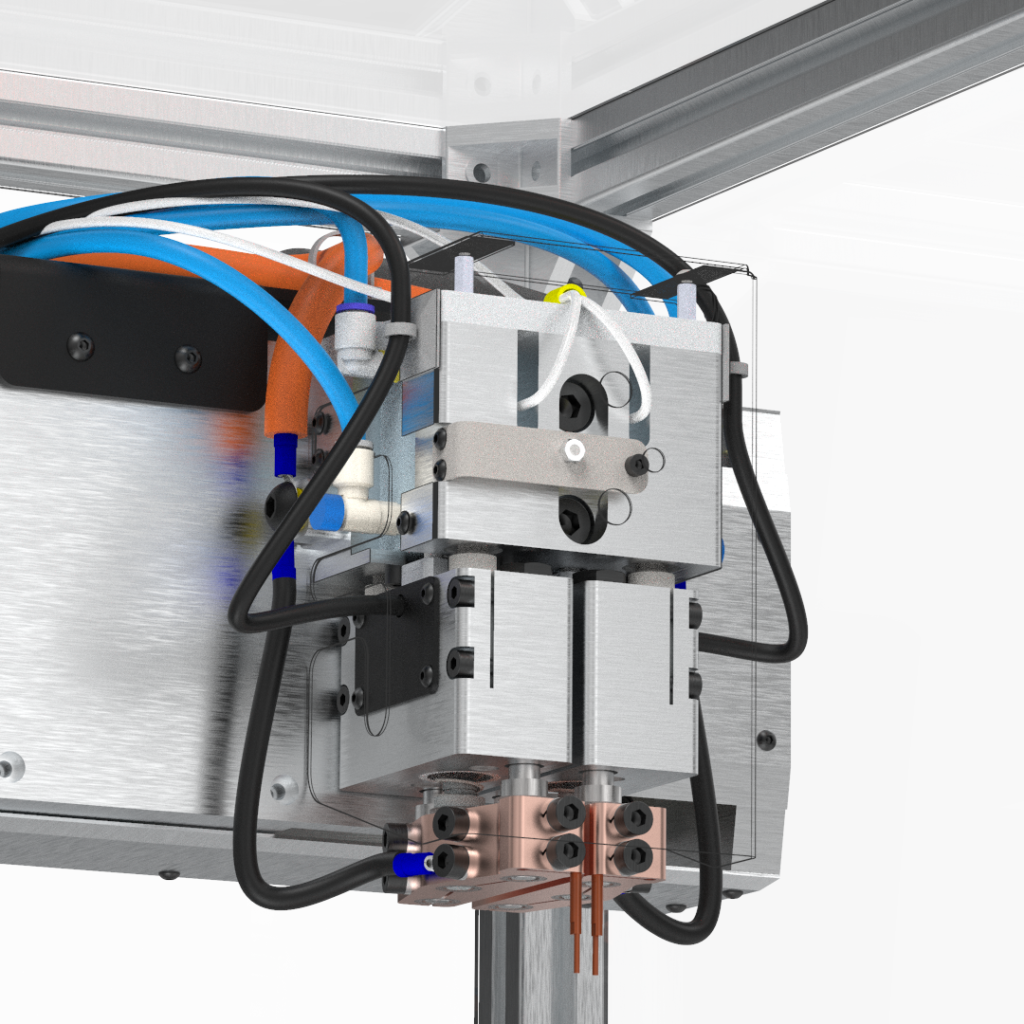

Precision Pnuematic Spot Head

Our Innovative Pneumatic Spotting Head, equipped with advanced safety features for enhanced precision and protection. Integrated load cells and Hall sensors ensure fail-safe operation, preventing misfiring of spots, while the spring-loaded design provides an added layer of safeguarding against potential cell punctures. Elevate your welding process with technology that not only guarantees accuracy but prioritizes the safety of your materials, setting a new standard for reliability in spot welding applications.

- Hall Sensors and Load Cell enabled

- Spring Loaded Design

- Laser Pointer for target setting

- Adjustable head height

Custom CNC Control

AutoSpot Custom CNC Controlled Welding System, an innovative solution developed on the robust Linux CNC platform. Featuring a meticulously crafted handmade GUI, this cutting-edge machine provides unparalleled accessibility for seamless control. The user-friendly interface offers real-time indications for faults, spot counts, and sensor detections, ensuring precise monitoring of the welding process.

Equipped with advanced pneumatic pressure detection, AutoSpot goes beyond conventional capabilities, enhancing safety and efficiency. Whether you’re a seasoned professional or a novice in welding, our custom CNC system simplifies operations, making intricate control adjustments effortless. Elevate your welding experience with a system that prioritizes precision, reliability, and user-friendly control, setting a new benchmark in the world of CNC-controlled welding technology.

- Real Time Sensor Status

- Head position Indication

- Step Jog mode

- Faults detection

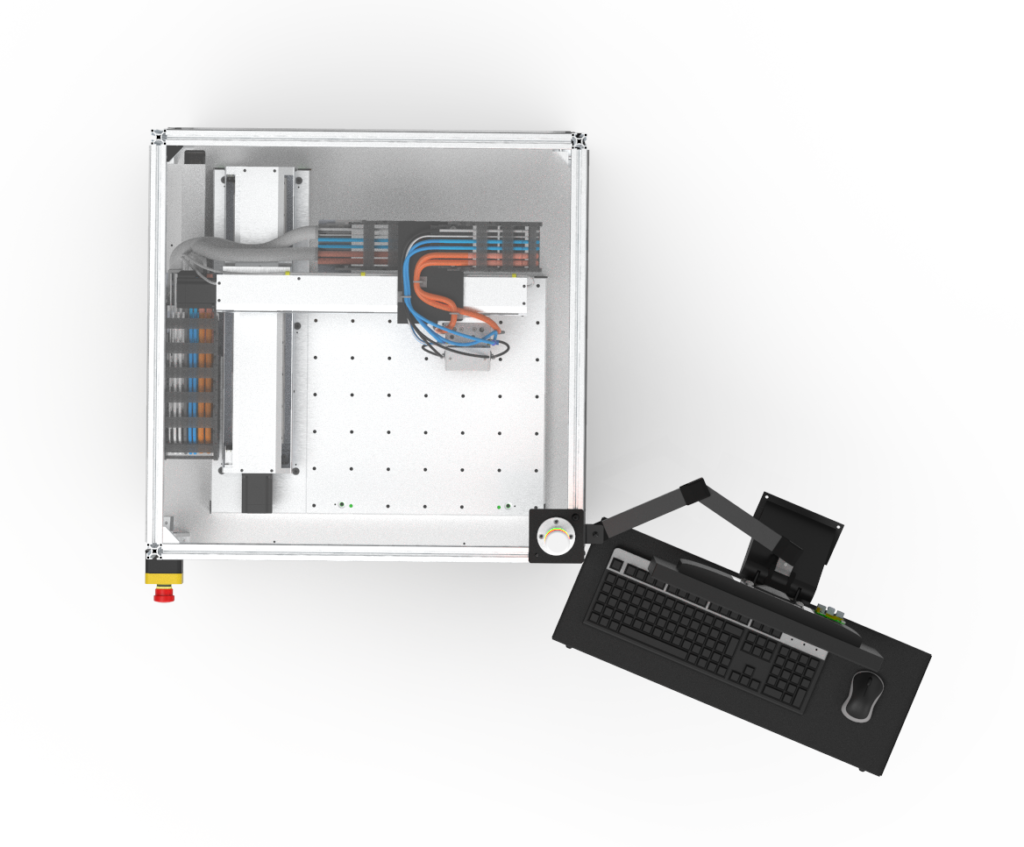

Small Form Factor

AutoSpot sets a new standard in spot welding machinery with its compact form factor measuring just 1.3 meters. Despite its space-saving design, this machine offers an expansive workable area of 400 x 400mm, providing versatility without compromise. The thoughtfully engineered structure not only enhances efficiency during operations but also facilitates straightforward installation and servicing, ensuring a user-friendly experience. Adding to its technological prowess, AutoSpot integrates a Raspberry Pi system, enabling seamless control and real-time monitoring of work status. Whether you are a seasoned professional or a novice, AutoSpot combines precision, convenience, and cutting-edge technology to redefine the landscape of spot welding, making it an invaluable asset in various industrial applications.

- 400 x 400 mm workable area

- Small floor area

- Easily Serviceable

- Raspberry pi OS

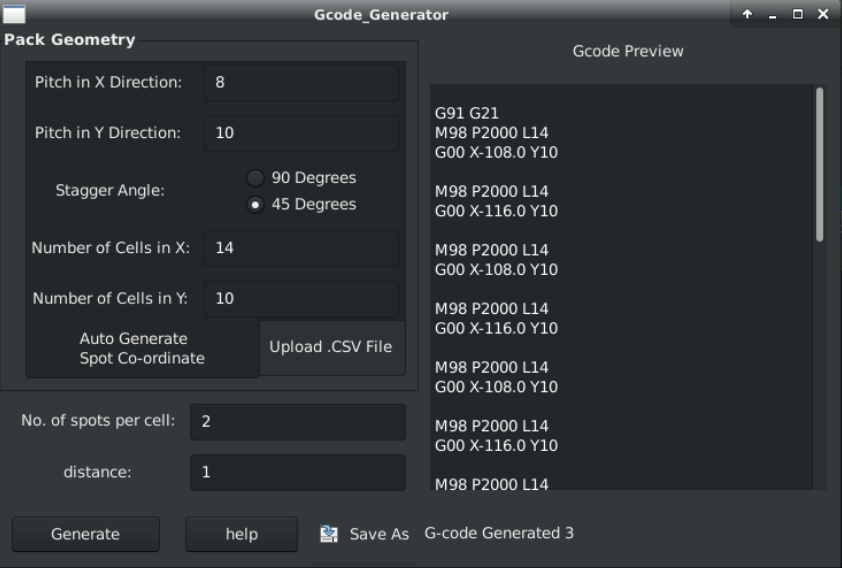

Automatic G-code generator

In addition to its advanced spot welding capabilities, AutoSpot further streamlines the user experience by offering a G-code generator. This feature effortlessly converts your design into G-code, providing control over various spot designs such as the honeycomb pattern and conventional square spots. Users have the flexibility to dictate the number of spots per cell, tailoring the welding process to specific requirements. Additionally, our CSV to G-code converter seamlessly translates intricate point data into G-code, facilitating precision welding for complex shapes. With AutoSpot, the convergence of cutting-edge technology and user-friendly tools empowers operators to achieve unparalleled accuracy and efficiency in spot welding operations.

- CSV To G-code

- Multiple spots on single cell

- Honeycomb and Square pattern

- Efficient g-code generation